TB42 Engine

Information on the Nissan TB42E engine

Haltech ECU Options

Supported with a Plug 'N' Play adaptor harness using an Elite 750 or Elite 2500 ECU for a Nissan Patrol Y60 model.

Can also be custom-wired using a universal harness and a Nexus R3 or R5 VCU.

General Information

| Engine specification | |

| Cylinders | 6 |

| Displacement | 4169 cc / 254 ci |

| Firing order | 1-5-3-6-2-4 |

| Cylinder orientation | Cylinder 1 is at the front of the engine |

Compression ratio | 8.3 : 1 |

Sensor Information

Crank and cam position sensor (Distributor)

This engine uses a crank position sensor and a cam position sensor located in the distributor as a single unit on the front of the engine. The sensor inside the distributor is an optical Hall-effect style, which has a dual sensor element that reads from a rotor plate with an outer 360-slit section (1°) and an inner 6-slit section (120°- one for each cylinder). The 6-slit section has five slits that are the same size and one slit that is larger, which is used for engine sync. The ECU looks at how many outer teeth occur during each of the six-slit intervals and uses this to start the sync for Cylinder 1.

Distributor wiring:

| Pin | Description | Haltech Connection |

| 1 | Signal Ground | Blue (Trigger 4-core) |

| 2 | +12V Switched | Red (Trigger 4-core) |

| 3 | 360x (Home) | Home+ Yellow (Home 4-core) |

| 4 | 6x (Trigger) | Trigger+ Yellow (Trigger 4-core) |

Note: On some Y60 Nissan Patrol models, the Trigger + and Home + pins may be wired differently compared to what is shown above. If full trigger synchronization cannot be achieved when the engine is cranked, swapping the Trigger + and Home + pins around may be required.

Trigger and Home wiring hack (when wiring a Haltech universal harness)

In the grey shielded "Trigger" 4-core cable, there are four wires: +12V, signal ground, Trigger+, and Trigger-. To wire this to the distributor, we need to connect all wires except for Trigger-.

In the grey/black shielded "Home" 4-core cable, we only need to connect the Home+ wire to the distributor.

A common hack to simplify wiring when using a Haltech universal harness is to re-pin the green Trigger- wire on the ECU end so it goes to the Home+ pin. This way, we can have all the required wires in a single 4-core cable (i.e., the 4-core "Trigger" cable), allowing the 4-core "Home" cable not to be used and optionally removed from the harness, making the main harness branch much simpler.

1. De-pin the Yellow wire from ECU pin A32 and insulate it. It will not be used.

2. De-pin Green wire from ECU pin A33 and move it to pin location A32.

For Elite 1000 / 1500 / 2000 / 2500:

1. De-pin the Yellow wire from ECU pin B2 and insulate it. It will not be used.

2. De-pin the Green wire from ECU pin B5 and move it to pin location B2.

1. De-pin the Yellow wire from ECU pin B2 and insulate it. It will not be used.

2. De-pin the Green wire from ECU pin B5 and move it to pin location B2.

For Nexus R3 / R5:

1. De-pin the Yellow wire from ECU pin C3 and insulate it. It will not be used.

2. De-pin the Green wire from ECU pin C2 and move it to pin location .

1. De-pin the Yellow wire from ECU pin C3 and insulate it. It will not be used.

2. De-pin the Green wire from ECU pin C2 and move it to pin location .

Trigger Configuration

Ignition System

The TB42E engine uses an external igniter and ignition coil that feeds the spark to the distributor. When wiring a Haltech ECU, Ignition Output #1 must be connected to the igniter, which then drives the ignition coil. Do not wire the ECU directly to the factory ignition coil, as ECU damage will occur.

Dwell Time

Suggested dwell time:

Ignition system upgrade

A common performance upgrade is to change the ignition coil to one with higher output. When doing so, it is recommended to use a coil with a built-in igniter, such as the Haltech IGN-1A ignition coil (HT-020114) or LS1 coil (HT-020102). These coils can be safely wired directly to the ECU (Ignition output #1), as they only require low current signals to be driven due to the igniters built into the coil assembly.

NOTE: Please refer to the product insert that comes with these Haltech ignition coils for wiring and software setup instructions.

Injector Data

Flow

The injector flow rate is measured with the injectors held wide open at 100% duty. For fuel systems with a fixed regulator pressure (often returnless systems) that is not referenced to manifold pressure the flow needs to be mapped over Manifold Pressure for accurate tuning.

TB42E Injector Flow: ~260cc/min

Dead Time

When an injector is commanded to open for a certain amount of time, the dead time is the amount of time the injector is not actually open during this period. It covers the time to energise the solenoid and begin to open and the time to close as well. There are also transient periods during which the injector is opening and closing where fuel flow is not at full capacity so this lost peak flow period is also taken into account.

Injector Wiring

Elite 750, 950, 2000, 2500 | Nexus R3, R5 - Wire injector output number as per cylinder number. i.e. 1 goes to 1, 2 goes to 2, etc..

| Haltech Connection | Injectors to Connect |

| Injector Output 1 | Injector 1 |

| Injector Output 2 | Injector 2 |

| Injector Output 3 | Injector 3 |

Injector Output 4 | Injector 4 |

Injector Output 5 | Injector 5 |

Injector Output 6 | Injector 6 |

Elite 550/1000/1500 - Elite 550/1000/1500 - Using these ECUs is not recommended as they do not have enough injector outputs to fire the injectors in full sequential mode. However, it is still possible to use these ECUs by wiring the injectors semi-sequentially, sharing two injectors with one output. The suggested pairing should be:

| Haltech Connection | Injectors to Connect |

| Injector Output 1 | 1+6 |

| Injector Output 2 | 2+5 |

| Injector Output 3 | 3+4 |

MAP Sensor

These engines do not come with a MAP sensor. You can use the internal MAP sensor that comes with your Haltech ECU, which is a 4-bar MAP sensor (rated up to 43 psi), or wire an external MAP sensor using a spare analog voltage input (AVI).

Throttle Position Sensor

The engine uses a Throttle Position Sensor (TPS) with two connectors: a round connector that provides a variable signal depending on the throttle angle, and a square connector that sends out a digital switched signal when the throttle is fully open or fully closed. Haltech ECUs only require connection to the variable sensor (round connector), as the ECU can determine the fully open and fully closed throttle states from the calibrated TPS signal.

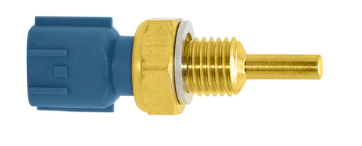

Coolant Temperature

Pin

Haltech Connection

1

Any Spare AVI*

2

Signal Ground

Note: Wiring is not polarity sensitive for two pin temperature sensors.

*An AVI with a selectable pull-up should be used. If not, an external 1k pull-up to 5V should be connected.

NSP software built-in calibration file: Use "Temperature - Nissan TB42E Y60 Coolant Sensor.cal"

(Created for Haltech ECUs using a 1k pullup to 5V)

| Pin | Haltech Connection |

| 1 | Any Spare AVI* |

| 2 | Signal Ground |

Note: Wiring is not polarity sensitive for two pin temperature sensors.

*An AVI with a selectable pull-up should be used. If not, an external 1k pull-up to 5V should be connected.

Air Temp

The TB42 engine does not come with an Air Temp Sensor. A Haltech Air Temp Sensor should be added.

Haltech 1/8" NPT Air Temp Sensor (HT-010206)

Pin

Haltech Connection

1

Any Spare AVI*

2

Signal Ground

Note: Wiring is not polarity sensitive for two pin temperature sensors.

*An AVI with a selectable Pullup should be used. If not and external 1k pullup to 5V should be connected.

NSP software built-in calibration: Use "Temperature - GM Air Sensor.cal"

(Created for Haltech ECUs using a 1k pullup to 5V)

Haltech 1/8" NPT Air Temp Sensor (HT-010206)

| Pin | Haltech Connection |

| 1 | Any Spare AVI* |

| 2 | Signal Ground |

Note: Wiring is not polarity sensitive for two pin temperature sensors.

*An AVI with a selectable Pullup should be used. If not and external 1k pullup to 5V should be connected.

Idle Air Control Valve

TB42E engines come with two separate idle air control valves: the larger solenoid valve, which Nissan calls the AAC valve (Auxiliary Air Control), and the smaller solenoid valve, which is the FICD valve (Fast Idle Control Device). The AAC solenoid valve requires a +12V power source that is switched with ignition power, and the other pin is controlled with any spare ECU output. This solenoid operates variably using a PWM signal from the ECU. The higher the duty cycle commanded, the more the valve opens to bypass air into the intake system to give a higher idle speed. The smaller FICD solenoid is a switched-type valve mainly used when the A/C clutch is engaged and does not need to be controlled by the ECU, as it can be wired to switch open whenever the aircon compressor engages.

MAF Sensor

Most users will delete the Mass Air Flow sensor (also known as the Air Flow Meter) and replace it with a Manifold Absolute Pressure (MAP) sensor for Speed-Density type tuning. However, the wiring for the Mass Air Flow sensor is provided below for those who prefer to use it.

O2 Sensor

The TB42E engine uses a narrowband 1-wire O2 sensor, which can be wired to the ECU using an analog voltage input.

| ECU | Recommended Haltech connection |

| Elite 750 | AVI 1 |

| Elite 2500 | AVI 1 or AVI 6 |

| Nexus series | Any AVI |

Adding a Haltech Wideband O2 sensor kit (highly recommended)

Although the engine uses a factory O2 sensor (narrowband), it is highly recommended to replace this sensor with a Haltech WB1 wideband sensor kit. Using a wideband sensor allows the engine to be tuned at any RPM and engine load combination. The ECU can also use this sensor as a feedback sensor for closed-loop fuel control (O2 control) across a wide range of operating conditions, as well as to implement engine lean-out protection strategies.

HT-159976 - WB1 Bosch Single Channel CAN O2 wideband controller kit (recommended for Elite ECUs)

HT-010746 - LSU 4.9 wideband hardware pack (recommended for Nexus series ECUs with onboard wideband control)

Vehicle Speed Sensor

The Vehicle Speed Sensor on the TB42E is a two-wire sensor that connects directly to the speedometer on the Y60 Patrol. The speedometer then sends a filtered digital signal to the ECU. This means that if you don't have the factory speedometer (gauge cluster), such as when replacing it with a digital dash, the ECU will need to be wired directly to the sensor.

OEM ECU Information

Location

The factory Nissan Patrol Y60 TB42 ECU is located in the passenger side footwell. Lifting the carpet will expose the factory ECU and allow the installation of the Haltech ECU.

ECU wiring diagram

Base Maps

Coming soon...

Related Articles

Nissan CAS – Facts and Fiction

The Hot Debate One of the most hotly debated topics within the global RB community is the accuracy of the Nissan OEM Cam Angle Sensor (CAS). In this article we will attempt to separate facts from fallacies, explain the cause of the problem and ...TB48 Engine

Information on the Nissan TB48DE engine Haltech ECU Options Supported as a plug in with the Platinum Pro Y61 ECU (Note: this ECU is no longer sold by Haltech). Engine is supported by wiring in an Elite 750 or Elite 2500. General Information Cylinders ...FJ20ET Engine

Information on the Nissan FJ20ET engine. The naturally aspirated FJ20E and FJ24 are not covered by this guide. Haltech ECU Options All Haltech Elite ECU models support this engine General Information Cylinders 4 Displacement 1990 cc Firing Order ...RB20/25/26 Engine

The RB series of engines are among the most popular and desirable engines in today's enthusiast society. There is no other engine that sounds quite like a twin cam RB. They are known for a power-band that is smooth and increases as it progresses ...TB45 Engine

Information on the Nissan TB45 engine Haltech ECU Options Haltech has plug in ECU options for this model. https://www.haltech.com/product-category/nissan/patrol-y61/ General Information Cylinders 6 Displacement 4479 cc / 273.3 ci Firing Order ...