Honda K Series Engine

General Information

| Haltech Elite Series Setting | Value |

Number of Cylinders | 4 |

Capacity | 1998cc 2.0L or 2354cc 2.4L |

Firing Order | 1-3-4-2 |

Engine Type | Piston 4 - Stroke |

Injection Mode | Sequential |

Number of Inj | 4 |

Inj Flow/Size | 310cc |

Inj Current Setting | High |

Ignition Mode | Direct Fire |

Ignition Edge | Falling |

Ignition Dwell Mode | Constant Charge |

Trigger Tooth Pattern | 12+1 |

Home Tooth Pattern | 4+1 (exhaust cam) |

ESP Trigger Pattern | Honda K20 |

TDC Angle | 311 |

Trigger Sensor Type | Hall |

Trigger Sensor Edge | Falling |

Trigger Filter Level | 0 |

Trigger Pullup | Strong |

Trigger Ground Ref | - |

Home Sensor Type | Hall |

Home Sensor Type | Falling |

Home Filter Level | 0 |

Home Pull-up | Strong |

Home Ground Ref | - |

Home Min RPM | 1000 |

Quick Start | Enabled |

Notes | This applies for the following : K20A/K24A DC5/EP3 K20Z1 |

Recommended Haltech ECU

https://www.haltech.com/product/ht-150802-elite-1000/

https://www.haltech.com/product/ht-150804-elite-1000/

Sensor Information

Trigger System

Exhaust 4+1 teeth

Intake 4 teeth

Trigger Configuration

Crank Sensor (CKP)

Wiring

K20 Crank Sensor Wiring (Blue Connector)

Pin | Description | Haltech Connection (Trigger 4-core) |

1 | Signal | Trigger + |

2 | Signal Ground | Signal Ground |

3 | 12V+ Swtiched | 12V+ |

| Pin | Description | Haltech Connection (Trigger 4-core) |

| 1 | 12V+ Switched | 12V+ |

| 2 | Signal | Trigger + |

| 3 | Signal Ground | Signal Ground |

Cam Sensor

1 | 2 | 3

Pin | Description | Haltech Connection |

1 | Signal - Intake Cam (Blue/White) | SPI Input - assign to Cam Control function |

2 | 0V Brown/Yellow | Signal Ground |

3 | 12V Yellow/Black | 12V |

| Pin | Description | Haltech Connection (Home 4-core) |

| 1 | Signal - Exhaust Cam (Green) | Home + |

| 2 | 0V Brown/Yellow | Signal Ground |

| 3 | 12V Yellow/Black | 12V |

Ignition System

Pin | Description | Haltech Connection |

1 | ECU Signal | Ignition Output |

2 | Ground to Cylinder Head | --- |

3 | 12V+ Switched | --- |

Dwell

Injector Data

Flow

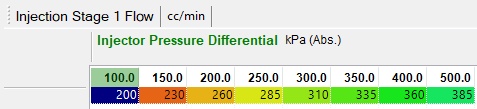

The injector flow rate is measured with the injectors held wide open at 100% duty. For fuel systems with a fixed regulator pressure (often returnless systems) that is not referenced to manifold pressure the flow needs to be mapped over Manifold Pressure for accurate tuning. The K20 has a non-returning fuel system with a pressure regulator not connected to inlet manifold pressure. As such teh injector flow rate should be mapped over Injector Pressure Differential to maintain correct injector flow with changing manifold pressure.

If a fuel pressure sensor is not connected then the Base Fuel Pressure setting will impact the fuel control.

Dead Time

When an injector is commanded to open for a certain amount of time, the dead time is the amount of time the injector is not actually open during this period. It covers the time to energise the solenoid and begin to open and the time to close as well. There are also transient periods during which the injector is opening and closing where fuel flow is not at full capacity so this lost peak flow period is also taken into account.

Variable Cam Control (iVTEC and VTEC)

Cam Control (iVTEC)

Cam Control Switched (VTEC)

System Description

Why does Honda impletment this system? They implement it to improve optimum engine effeciency which results in more horsepower and better fuel economy. Since the camshaft spins half as fast as the crankshaft, optimum valve over-lap and timing is different at every RPM.

Muscle cars have that lope at idle because of the camshaft design. By designing a camshaft specifically for high RPM horsepower, you must use sacrifice how smooth the engine runs at low RPM. This sacrifice is what causes the engine lope at idle.

VTEC-E

VTEC-E is quite different from the standard VTEC, because Honda did not design it for optimal horsepower at high RPMs, instead they designed for optimal fuel efficiency at low RPMs. VTEC-E does this by effectively forcing the engine to run as a 12 valve engine instead of its normal 16 valves. It does this by not allowing the second intake valve to open fully

The VTEC-E design decreases fuel consumption quite a lot but lacks the high horsepower numbers that the standard VTEC produces. This type of VTEC is standard on many of the fuel-efficient Honda models.

VTC

Before we jump into i-VTEC, we quickly want to cover VTC to give you a better understanding of how all this works. Variable Timing Control (VTC), is a mechanism that allows the camshaft gear to be continuously variable. The variable camshaft gear allows the valve overlap to be adjusted at any RPM. By adjusting the valve overlap agt different RPM ranges, effeciency and power levels are greatly improved.

Honda uses this system on the intake camshaft but not on the exhaust camshaft, as the gains from having VTC on the exhaust camshaft are minute. VTC is always active and adjusting valve overlap for optimal engine efficiency and power at any given RPM.

iVTEC

Intelligent Variable Timing (and lift) Electronically Controlled (iVTEC), is a system that combines VTEC and VTC into one unit. As you can imagine, combined the best of both world results in an incredibly efficient and powerful engine. The VTEC part of the system has two different camshaft profiles, one for low rpms, and one for high rpm. The VTEC part of the system allows valve overlap to be adjusted at any moment, resulting in much greater efficiency and slightly better performance.

K20A2: The K20A2 VTEC system engages at 5,800 RPM, whilst the VTC system is always active. These two systems combined (iVTEC) produce about ten horsepower more than just VTEC alone. The K20A2 is available in the Acura RSX Type S, and TSX.

K20A3: The K20A3 iVTEC system is far different than the A2’s system. It is VTEC-E with VTC, and really shouldn’t even be classified as iVTEC. At low RPM only one intake valve opens, which decreases fuel consumption, then at 2,200 rpm, it engages the second intake valve, allowing it to operate like a normal 16 valve engine.

Much like the A2’s iVTEC system, the VTC is always active on the A3. K20A3 comes in the RSX base, Civic SI, Accord, CRV, and Element.

How Does it Increase Horsepower?

How the VTEC system increase horsepower may be slightly confusing, so let me break it down for you. Horsepower is just a measure of Torque X RPM. To increase torque, you must let more air and fuel into the engine.

If the valves must open further and for longer, the amount of air being sucked into the cylinder can be increased. Since the camshaft spins half as fast as the crankshaft, it cannot be optimized for all RPM ranges. Having multiple camshaft lobes allows you to maximize lift and duration for various RPM ranges.

Since the camshaft is optimized for both high and low rpm ranges, it makes more torque in those ranges. More torque, especially at high RPMs, equals more horsepower.

Summary

There is a lot of information to take in. Remember, iVTEC combines VTEC and VTC into one unit in the K20A2. iVTEC in the K20A3 is a combination of VTEC-E and VTC, which is much more of a fuel efficiency focused system.

Throttle Position Sensor (TPS)

Pin | Description | Haltech Connection |

1 | Signal Ground | Signal Ground (Black/White) |

2 | Signal | Spare AVI (AVI-10 White) |

3 | 5V+ | 5V (orange) |

MAP Sensor

Pin | Description | Haltech Connection |

1 | 5V+ | 5V+ (orange) |

2 | Signal | Spare AVI (AVI-9 Yellow) |

3 | Signal Ground | Signal Ground (black/white) |

Vehicle Speed Sensor

Pin | Description | Haltech Connection |

1 | Signal Ground | Signal Ground (Black/White) |

2 | 12V+ | --- |

3 | Signal |

| Pin | Description | Haltech Connection |

| 1 | 12V+ | --- |

| 2 | Signal | |

| 3 | Signal Ground | Signal Ground (Black/White) |

OEM ECU

ECU Pinout

Related Articles

Honda / Acura B Series Engine

The B-Series engine was offered in Integras, Civics, Preludes, Accords, CRXs, Del Sols and CRVs. This engine had 28 different engine codes. The letter B is normally followed by two numbers to designate the displacement of the engine, another letter, ...What’s So Special About Honda’s K-series

Honda’s contribution to motorsport and the JDM performance scene is unquestionable and today we’re going to take a closer look at what is arguably the most popular “modified” Honda engine – the K-series. Once upon a time in Japan…. Let’s start with a ...LY7 LE0 Alloytec Engine

Information on the GM LY7 High Feature Alloytec V6 engine. It will be referred to in this guide as the Alloytec. Haltech ECU Options The Elite 2000 can be used without DBW, the Elite 2500 is required with DBW. General Information Cylinders 6 ...Extra Sensory Perception. What Sensors Do I Need ?

One of the questions we get asked quite often is: What sensors are required in order to run an aftermarket ECU? While there are many additional sensors you can fit to further increase the functionality of your ECU, there are some that are essential ...Check Sensors

Once you can go Online with the Elite Software Programmer, the next step is to check the various sensors connected. The easiest to check is the TPS. Move the throttle and check for movement of the TPS signal. Take the opportunity to calibrate your ...